Capabilities

Craftsman’s diverse manufacturing and design capabilities enables us to provide end-to-end engineering solutions for our diverse clientele.

Our capabilities include product design, precision machining, full gamut of casting, precision assembly, welding & fabrication, and allied processes such as surface and heat treatment. Coupled with in-house process and tool design, we also assist customers to optimize product and process design for better manufacturability and cost optimization.

Strong IN-House Process and Product Design Capabilities...

-

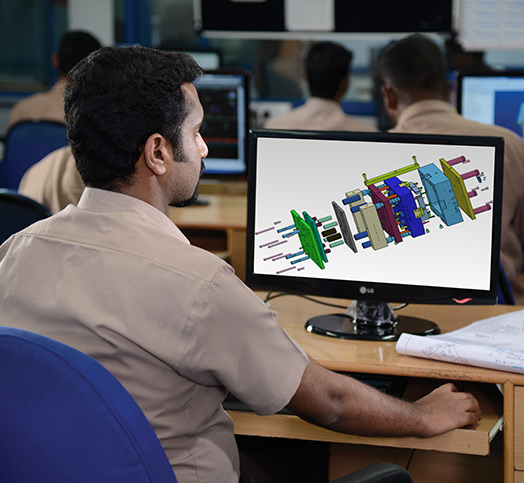

Product and Part Design & Simulation

-

Manufacturing Process Design, tool (die) and fixture design and manufacturing

-

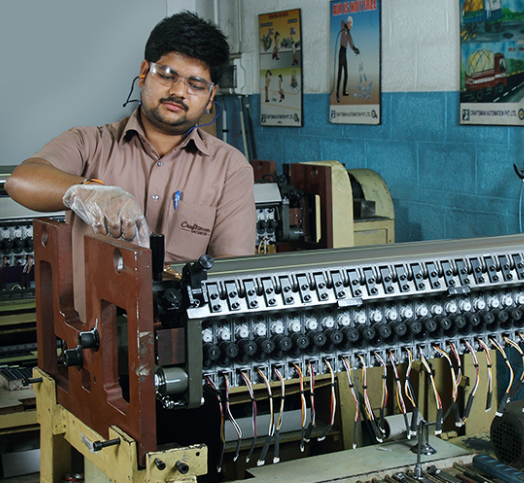

Special Purpose Machine Design & Manufacturing

-

Aluminium casting High Pressure, low pressure, gravity and sand casting

-

Machine, metal forming, Heat Treatment Gear Manufacturing, Sheet metal fabrication and powder coating

-

Assembly & Quality Assurance and Testing

…coupled with significant flexibility in manufacturing equipment.

-

Presence across value chain

Product design, prototyping, tool development, manufacturing, assembly and production of integrates and production of integrated components

-

Flexible plant configuration

Machinery is equipped for both indivuidual and diversified processess

-

Interchangeable usage of machinery

Enables company to optimize machine tool machine tool productivity, operational efficiency and time management

-

Dedicated production lines

Based on the size and frequency of the orders of their customers